rfid inlay chip What is an RFID inlay? An RFID inlay is a component of radio-frequency identification (RFID) technology. It consists of an RFID chip (also known as an integrated circuit or IC) attached to an antenna, typically embedded in a substrate material such as plastic or paper. $39.99

0 · wet rfid vs dry inlay

1 · rfid vs wet inlays

2 · rfid tags for zebra printers

3 · rfid lost freight labels 4x6

4 · rfid labels for zebra printers

5 · rfid inlays means

6 · rfid inlay manufacturers

7 · rfid catalog

$19.99

For more than 72 years, Metalcraft has provided customers worldwide with durable, high-quality barcode labels and RFID tags. But did you know that we also manufacture custom RFID inlays? Watch this video to learn more about our latest business venture, Inlay Innovation and how an inlay is created. . See morePartner with us to save time, money:For some RFID applications, constructing a custom inlay is a cost-effective way to optimize your RFID tags and achieve the desired outcome of . See more

Inlay Innovation offers world-class inlay manufacturing and testing capabilities, as well as the technical expertise that rivals those of any larger organization in the RFID industry. But . See more RFID (radio frequency identification) inlays are essential components in RFID .

What is an RFID inlay? An RFID inlay is a component of radio-frequency identification (RFID) technology. It consists of an RFID chip (also known as an integrated circuit or IC) attached to an antenna, typically embedded in a substrate material such as plastic or paper. RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process. To help you understand all the differences between tags, inlays, and labels, we’ll define the parts of RFID tags as below: Integrated Circuit. This part is also known as an RFID chip. It is the part of the tag that is responsible for data .We partner with all leading IC suppliers to develop world-class RFID products incorporating the latest chip technology. RAIN RFID inlays, tags and labels work in the Ultra-High Frequency Band and can provide a read range of up to 10 meters or 30 feet.

RFID tags, inlays, and labels are all used to identify and track objects, but they differ in their construction and application. Here's how: RFID Tags: RFID tags are small devices that contain an antenna and a chip for storing and transmitting data.

Unlock unbeatable tracking capabilities with our 74x24mm UHF RFID Wet Inlay, equipped with the market-leading Impinj Monza®4E chip. Designed for superior performance and ISO18000-6C compliance, this RFID wet inlay excels in delivering a long reading range and robust data security.

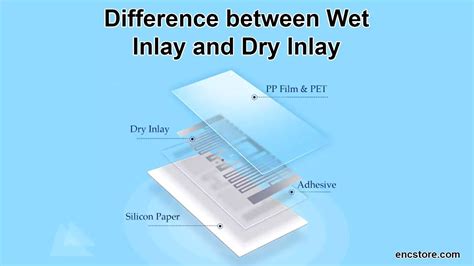

What is an RFID inlay? Functionally, an inlay consists of an antenna and a microchip. The antenna drives tag performance and governs how well the tag will work in a particular application. Precision-designed to receive and broadcast RF signals, the antenna is made from a conductive material (such as silver, copper or aluminum).From fully integrated labels to high-performing RFID tags, SML provides comprehensive GS1 (UHF) RFID inlay and tag products.Customize NFC/HF & UHF RFID Inlay. An RFID Inlay is just the RFID Chip (IC), Tag Antenna and Substrate, typically on a film face. If the substrate has adhesive it’s called a “Wet Inlay”. Otherwise, it’s called a Dry Inlay. The creation of RFID tags or labels involves a sophisticated manufacturing process known as the chip inlay process. This process includes the integration of the RFID chip and its antenna into the label, ensuring seamless functionality and durability.

What is an RFID inlay? An RFID inlay is a component of radio-frequency identification (RFID) technology. It consists of an RFID chip (also known as an integrated circuit or IC) attached to an antenna, typically embedded in a substrate material such as plastic or paper. RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process. To help you understand all the differences between tags, inlays, and labels, we’ll define the parts of RFID tags as below: Integrated Circuit. This part is also known as an RFID chip. It is the part of the tag that is responsible for data .We partner with all leading IC suppliers to develop world-class RFID products incorporating the latest chip technology. RAIN RFID inlays, tags and labels work in the Ultra-High Frequency Band and can provide a read range of up to 10 meters or 30 feet.

RFID tags, inlays, and labels are all used to identify and track objects, but they differ in their construction and application. Here's how: RFID Tags: RFID tags are small devices that contain an antenna and a chip for storing and transmitting data.Unlock unbeatable tracking capabilities with our 74x24mm UHF RFID Wet Inlay, equipped with the market-leading Impinj Monza®4E chip. Designed for superior performance and ISO18000-6C compliance, this RFID wet inlay excels in delivering a long reading range and robust data security. What is an RFID inlay? Functionally, an inlay consists of an antenna and a microchip. The antenna drives tag performance and governs how well the tag will work in a particular application. Precision-designed to receive and broadcast RF signals, the antenna is made from a conductive material (such as silver, copper or aluminum).

From fully integrated labels to high-performing RFID tags, SML provides comprehensive GS1 (UHF) RFID inlay and tag products.Customize NFC/HF & UHF RFID Inlay. An RFID Inlay is just the RFID Chip (IC), Tag Antenna and Substrate, typically on a film face. If the substrate has adhesive it’s called a “Wet Inlay”. Otherwise, it’s called a Dry Inlay.

wet rfid vs dry inlay

rfid vs wet inlays

rfid tags for zebra printers

rfid lost freight labels 4x6

rfid labels for zebra printers

Blank NFC cards come in a variety of durable, waterproof materials and are void of artwork. The most common NFC card is made of white rigid PVC in a standard CR80 (credit card) size. . NFC PVC Card - NTAG215 - 200 Pack. $49.98. .

rfid inlay chip|wet rfid vs dry inlay