rfid system tracking manufacturing In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.

OSRFID is a company that provides RFID Inlay&Label solutions. We focus on the development and manufacturing of soft HF/NFC/UHF labels and inlays. We have a 9,000 square meter .

0 · rfid tracking systems for inventory

1 · rfid tracking equipment and software

2 · rfid manufacturing inventory management

3 · rfid inventory tracking

4 · rfid based location tracking system

5 · rfid based asset tracking system

6 · rfid asset tracking software download

7 · asset tracking system using rfid

Your Country Leader. WHEP. Radio Baldwin. Q-94. America's Best Country. WRWW. The Red Arrow Sports Network. Listen to Stream Auburn Tigers (Football) here on TuneIn! Listen .

In the fast-paced world of manufacturing, keeping track of assets and inventory is . The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?

In the fast-paced world of manufacturing, keeping track of assets and inventory is paramount. That's where RFID (Radio Frequency Identification) tracking comes into play. By leveraging advanced technology, RFID offers seamless tracking and management of assets, paving the way for greater efficiency and reduced costs.

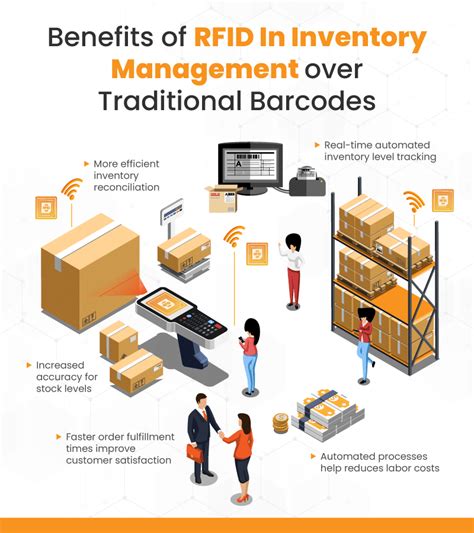

Using RFID in manufacturing is a smart move for anyone looking to improve asset tracking and gain real-time visibility into their operations. From reducing losses to optimizing workflows, the benefits are clear.RFID systems enable seamless tracking and tracing of goods throughout the supply chain, from manufacturing facilities to distribution centers and delivery vehicles. RFID tags identify and monitor shipments, optimize route planning, and streamline logistics operations, leading to faster delivery times, reduced transportation costs, and enhanced .

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory management, enhanced asset tracking, and increased operational efficiency.

rfid tracking systems for inventory

Transitioning to an RFID-based asset tracking system requires careful planning and execution. This section outlines a step-by-step approach for businesses looking to implement RFID for asset location and tracking effectively.

Radio frequency identification (RFID) technology has revolutionized asset tracking across various industries, and manufacturing is no exception. RFID offers a transformative approach to asset management, enabling real-time visibility, enhanced efficiency, and streamlined operations. RFID (Radio Frequency Identification) tracking systems are designed to improve the efficiency and accuracy of tracking and managing assets in manufacturing environments. By using radio waves, these systems can identify and track objects automatically, providing real-time data and insights.

RFID (Radio-Frequency Identification) technology significantly enhances Asset Tracking in manufacturing by offering increased visibility and control over assets. The key benefits include: Improved accuracy in locating assets, reducing the time spent searching for them.

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?

rfid tracking equipment and software

In the fast-paced world of manufacturing, keeping track of assets and inventory is paramount. That's where RFID (Radio Frequency Identification) tracking comes into play. By leveraging advanced technology, RFID offers seamless tracking and management of assets, paving the way for greater efficiency and reduced costs.

Using RFID in manufacturing is a smart move for anyone looking to improve asset tracking and gain real-time visibility into their operations. From reducing losses to optimizing workflows, the benefits are clear.RFID systems enable seamless tracking and tracing of goods throughout the supply chain, from manufacturing facilities to distribution centers and delivery vehicles. RFID tags identify and monitor shipments, optimize route planning, and streamline logistics operations, leading to faster delivery times, reduced transportation costs, and enhanced .

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory management, enhanced asset tracking, and increased operational efficiency.

Transitioning to an RFID-based asset tracking system requires careful planning and execution. This section outlines a step-by-step approach for businesses looking to implement RFID for asset location and tracking effectively.Radio frequency identification (RFID) technology has revolutionized asset tracking across various industries, and manufacturing is no exception. RFID offers a transformative approach to asset management, enabling real-time visibility, enhanced efficiency, and streamlined operations.

RFID (Radio Frequency Identification) tracking systems are designed to improve the efficiency and accuracy of tracking and managing assets in manufacturing environments. By using radio waves, these systems can identify and track objects automatically, providing real-time data and insights.

rfid manufacturing inventory management

contactless credit card skimmer

contactless cards usa

NATIONAL FOOTBALL CONFERENCE. Standings - Detailed View NFC Team W L T RANK . y : Clinched Wild Card ; z : Clinched Division .Find out which teams are winning the 2024 playoff race. Check out the NFL Playoff Picture for the latest team performance stats and playoff eliminations. Learn more.

rfid system tracking manufacturing|rfid based location tracking system